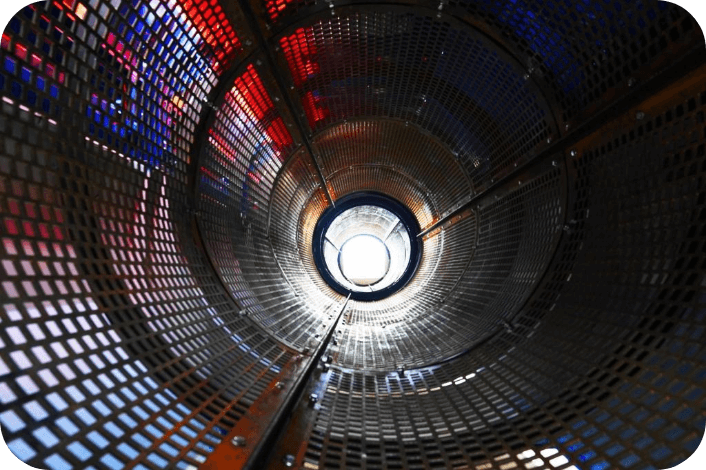

CRS Trommel Screens:

Available in various lengths and drum diameters depending on application requirements

CRS Heavy Duty Trommels are robust, customisable stationary screening solutions. They efficiently handle high material volumes up to 160 ㎥, sorting waste based on size. Versatile and efficient, they integrate easily into new or existing recycling setups.

Features & Benefits