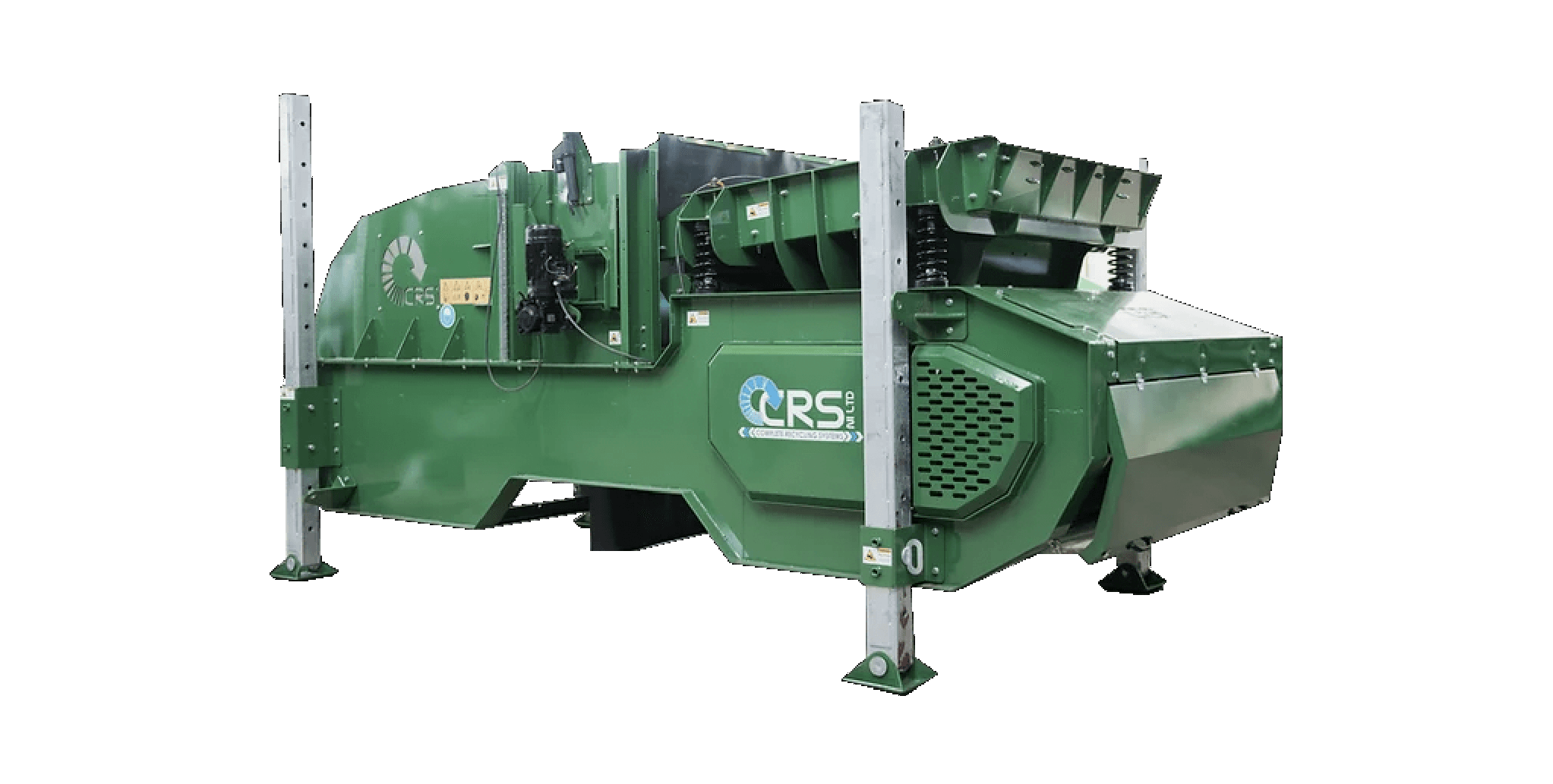

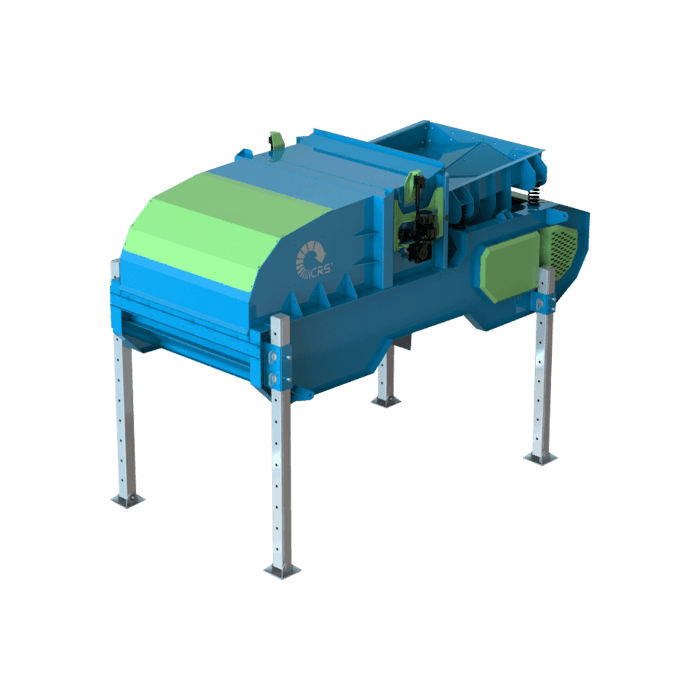

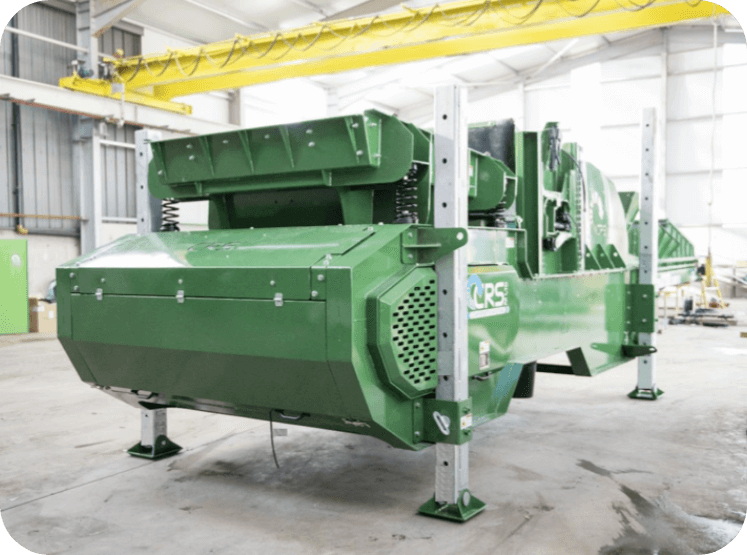

Mobile ASU Air Master: Innovative semi-mobile air separation unit for trommel fines recovery, featuring a vibrating feeder effectively separates light and heavy materials

The Mobile ASU Air Master from CRS NI Ltd is an advanced air separation unit that effectively separates light and heavy materials. Specifically engineered for recovering Trommel Fines, this semi-mobile system offers precision, efficiency, and flexibility, making it an invaluable addition to recycling operations across various industries.

Powered by two 11kW fans, the Air Master delivers strong performance while maintaining low costs. It offers flexibility in installation, with options as a standalone unit or integration into existing systems.

Fine-tuned control adjustments enable precise settings, enhancing efficiency. With low operational and maintenance costs, the Air Master is a reliable choice for air separation needs.

Features & Benefits