Our mobile waste recycling systems make sorting and

recycling your waste simpler and more cost-efficient!

Need to sort through, separate and grade mixed aggregates, fines, commercial and industrial waste, office waste, bio-waste or dry recyclable waste?

Our range of mobile machinery can be adapted to any waste management application.

Fully operational in a short period of time – and with an exciting array of features and optional extras,

they require no planning permission. What could be simpler or more cost-effective?

Mobile Tracked Screen: CRS – 038

The Mobile Tracked Screen can perform the processing and separation tasks that previously would have required two separate machines. The CRS-038 Mobile results in substantial savings for the customer in terms or capital outlay, running and service costs. It also requires a minimal footprint for operation making it suitable for the typical confined sites in towns and cities.

Features and benefits include:

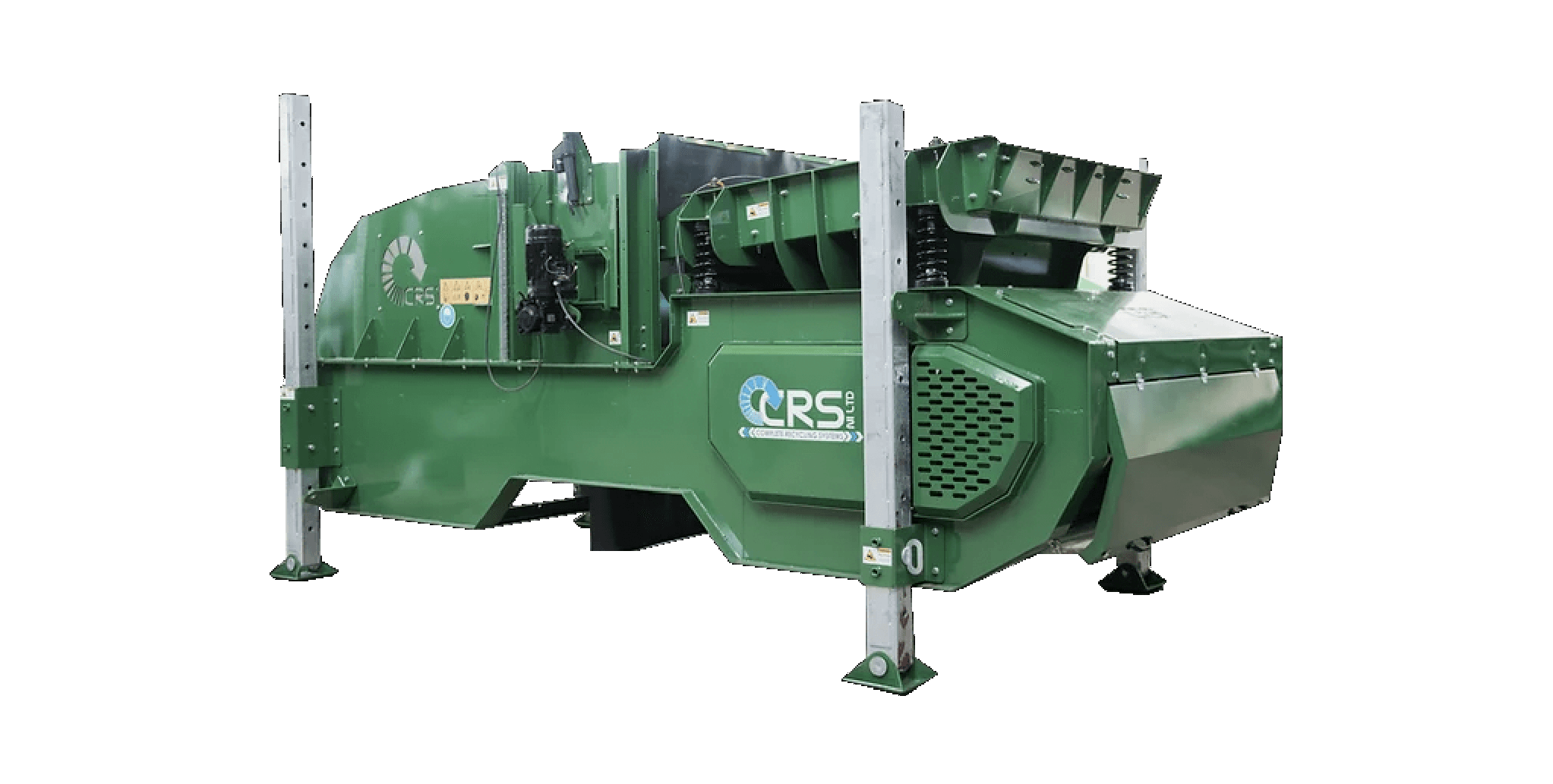

Mobile Picking Station CRS – 021

The machine’s typical use is in building and construction sites to retrieve valuable products, reducing what goes to the skip.

It is ideally placed to perform in towns and cities, with the ease at which it can be manoeuvred, along with quick set-up time of approximately 8 minutes.

On site set up is quick and safe using our wireless remote control allowing the operator to keep a safe distance during the set up procedure.

Features and benefits include:

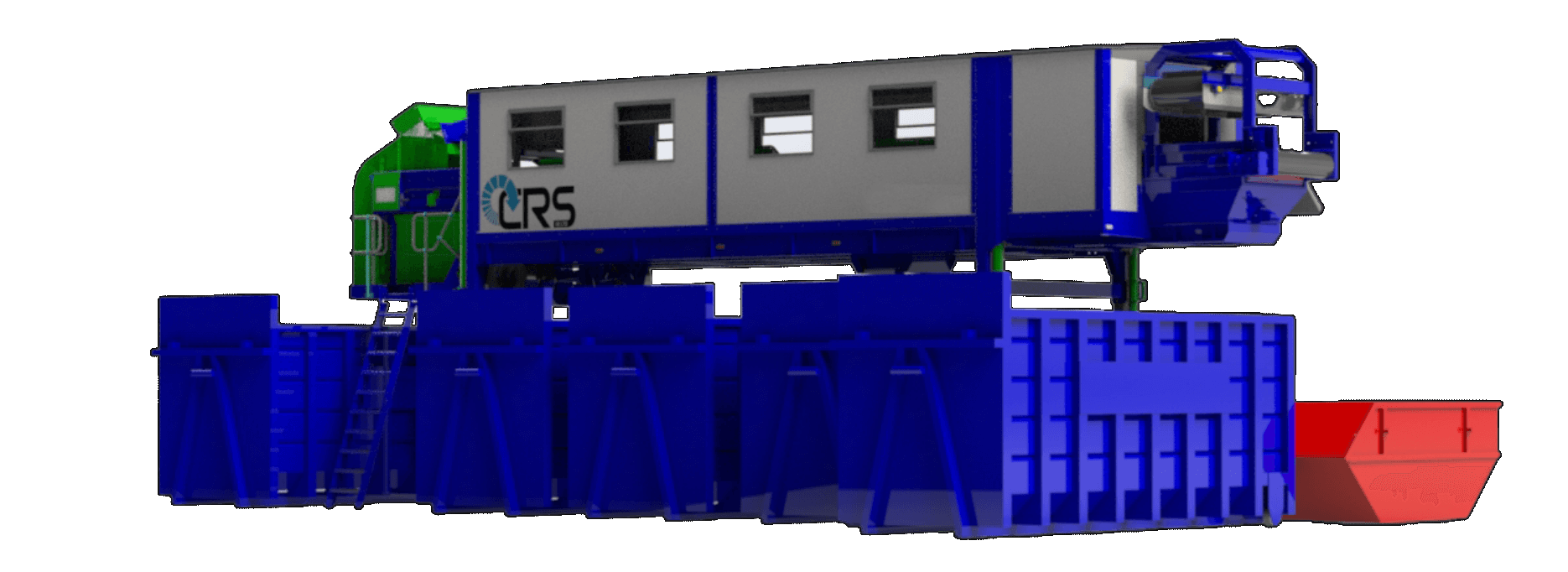

CRS – 021 – SM Picking Station

The CRS-021-SM Picking Station is a versatile and efficient waste recycling solution designed for sorting and separating recyclable materials. Available as a four bay, it is suitable for various applications and can be powered by diesel or mains electricity, making it adaptable for diverse site conditions.